Concrete inevitably contains pores and microcracks with size ranging from the nanometre to millimetre scales. The pore structure controls all major properties of hardened concrete including durability, strength, stiffness, shrinkage and creep. Penetration of external species such as chloride and sulphate ions, carbon dioxide and water occurs through the pore structure, and this is the main cause of concrete degradation.

However, the mechanism and dynamics of the transport and deterioration processes are poorly understood because the pore structure is inherently complex and time-dependent. This study aims to further develop backscattered electron microscopy to characterise and quantify the pore structure, in order to better understand its nature and influence.

Imaging

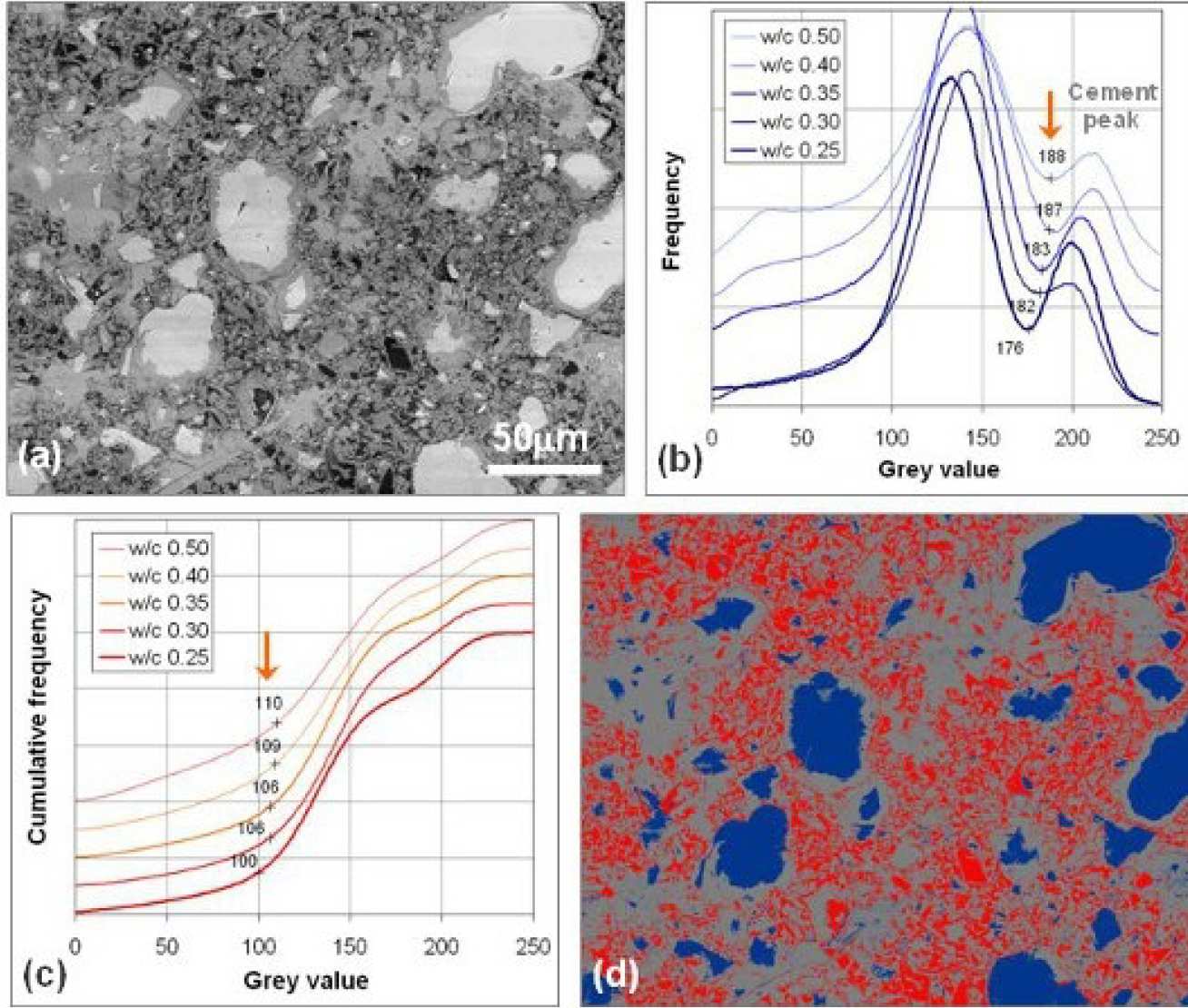

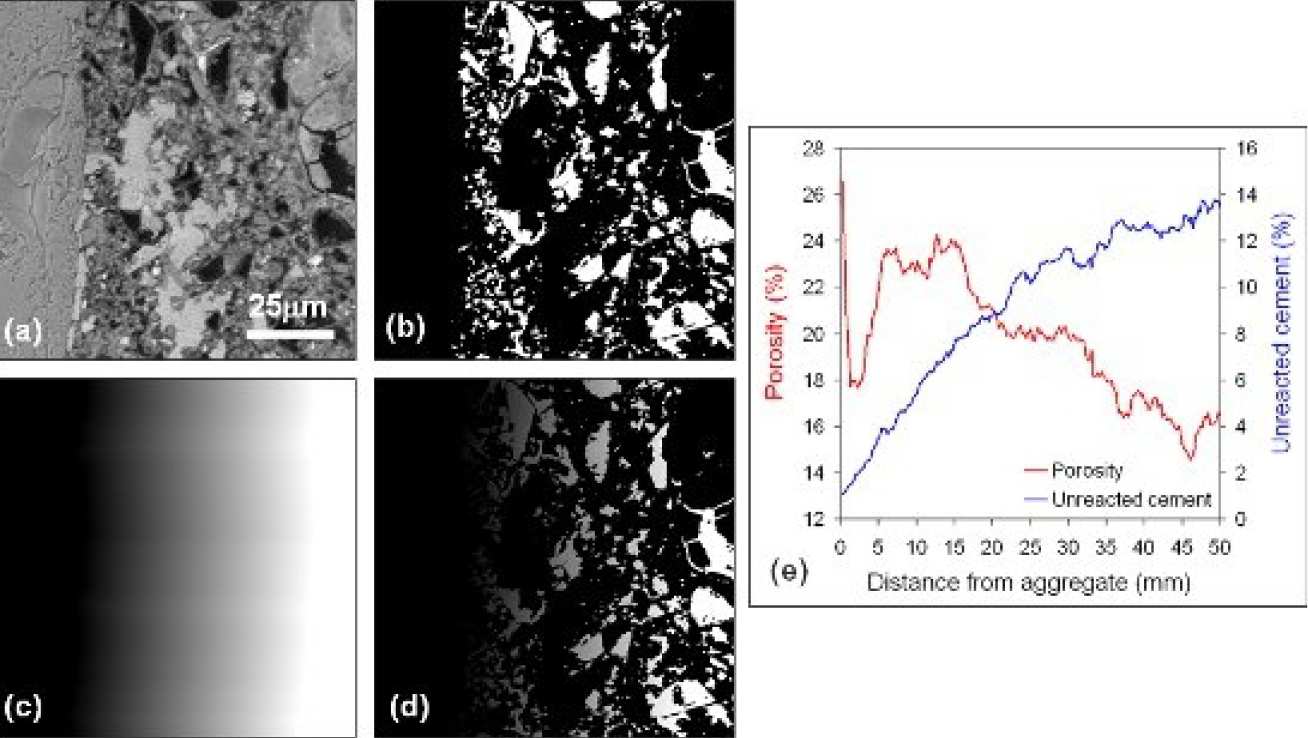

Backscattered electrons (BSE) are incident electrons that have re-emerged from the sample after undergoing elastic scattering. In a BSE image, the brightness of each pixel depends on the mean atomic number of the underlying phase, so pores and cracks appear darkest, followed by the aggregate particles, hydration products and unreacted cement. This allows various phases to be detected.

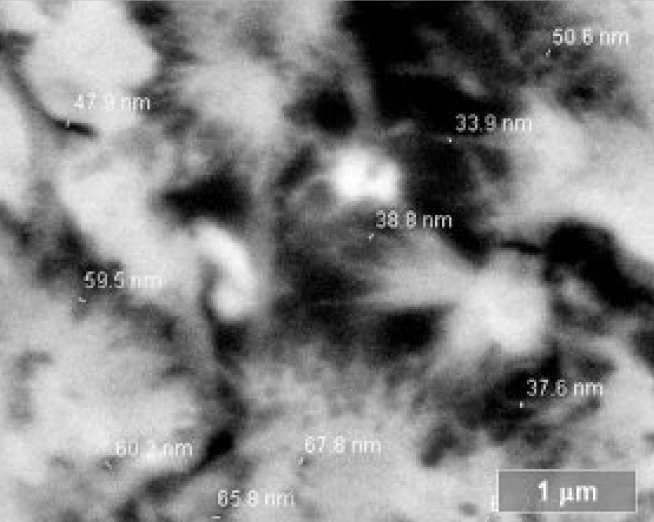

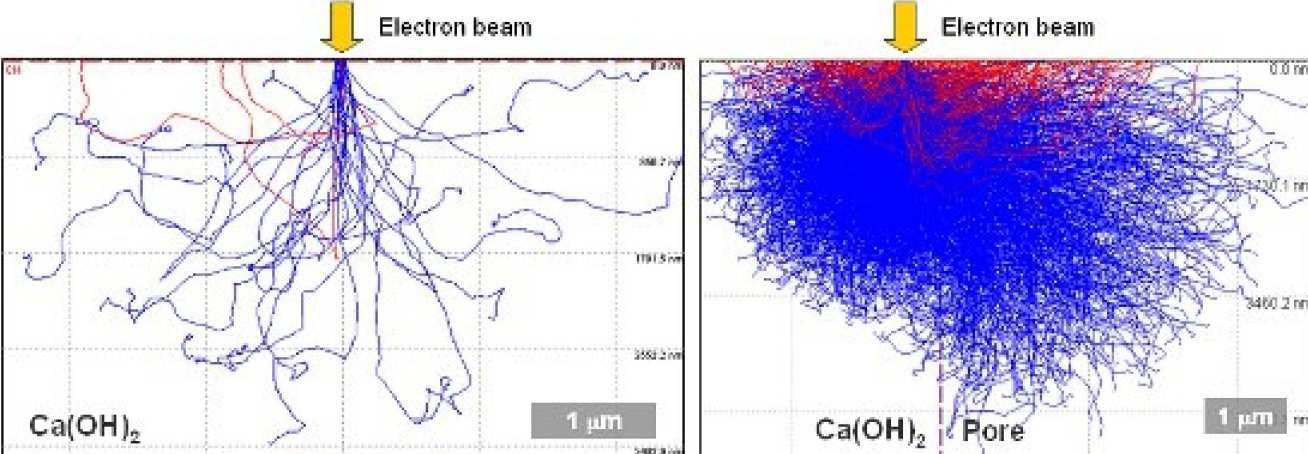

For high-resolution imaging, the sample must be fully impregnated with epoxy and flat-polished with diamond. Preparation damage and artefacts must be avoided and we have developed procedures to accomplish this1. In addition, a Monte-Carlo method (Fig. 2) was used to simulate the interactions between the electron beam and sample, in order to study the signal formation process in the scanning electron microscope2. This helps in the interpretation of the BSE images and determination of the optimal imaging condition, resolution limit and measurement errors.

Image Analysis

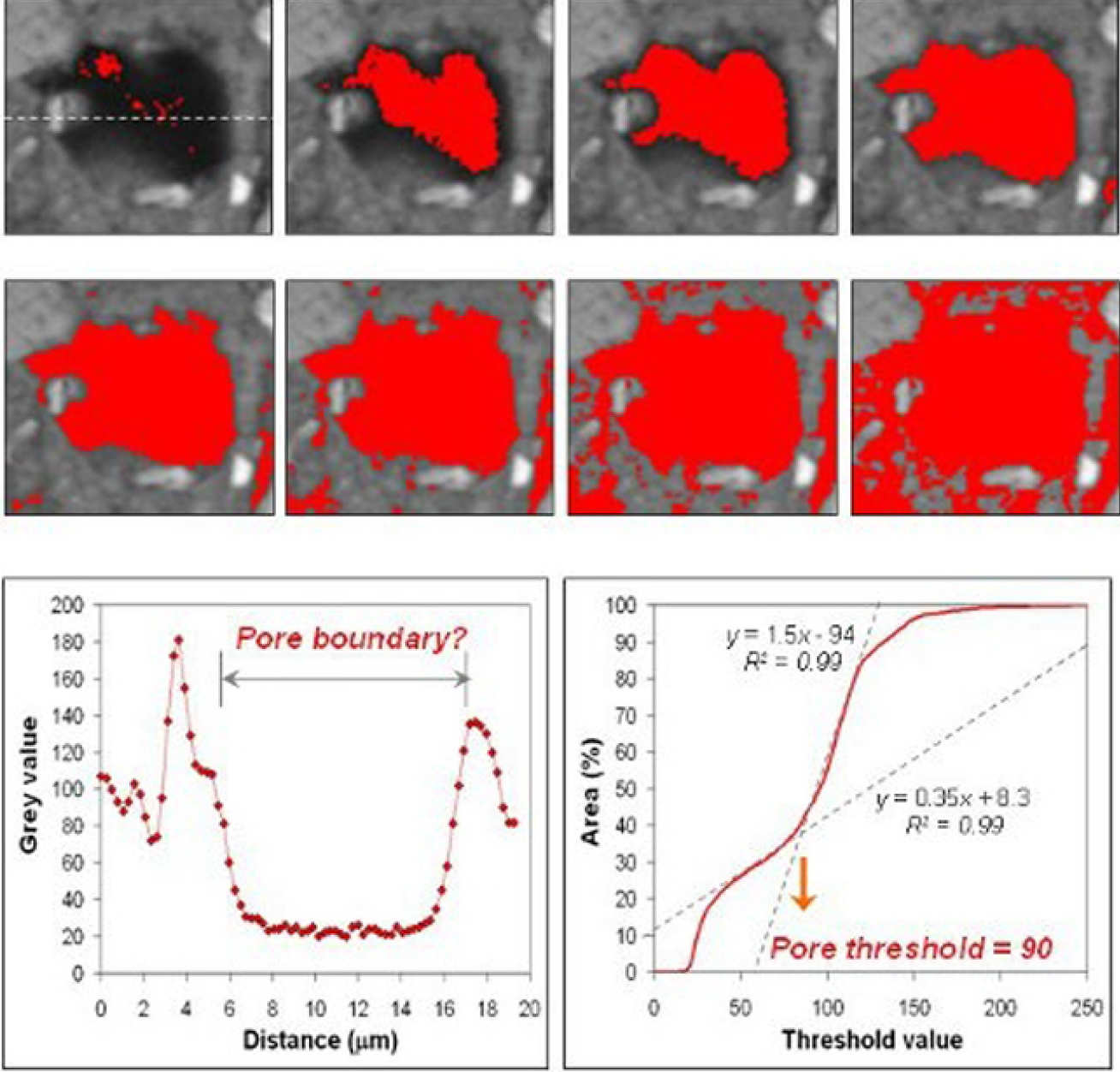

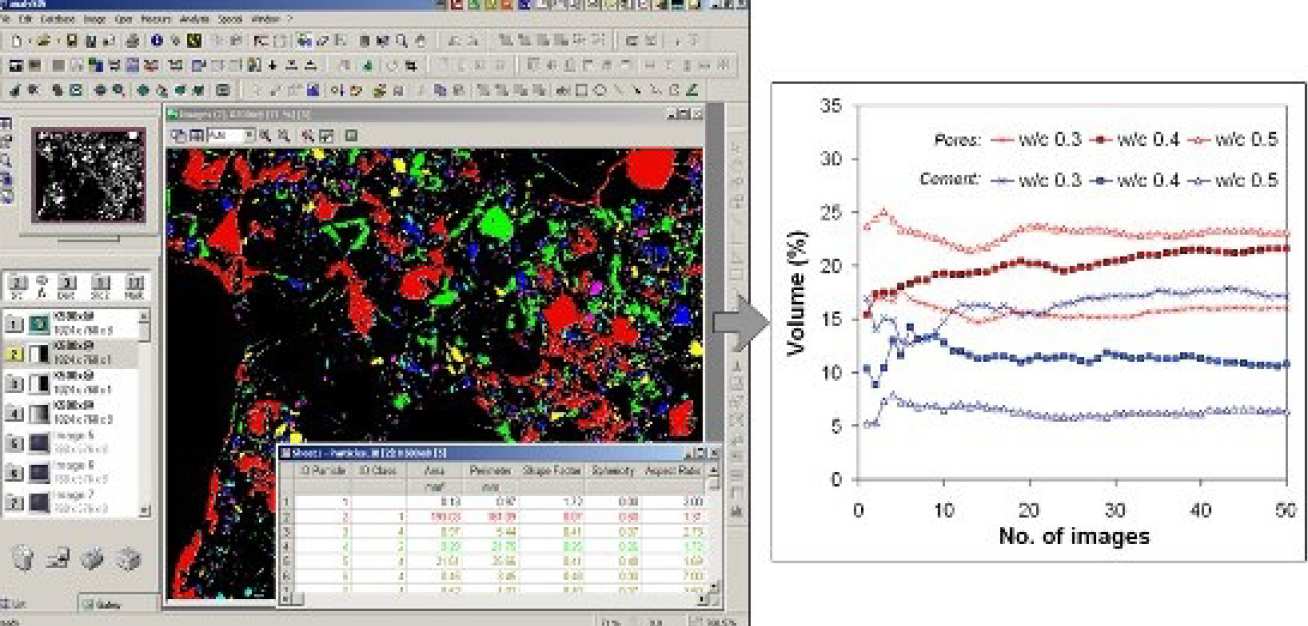

Once the microstructure is captured in digital format, a range of pixel-based measurements can be carried out using image analysis. The phases of interest are extracted using a segmentation algorithm that may involve brightness thresholding, edge detection, and size and shape filters. Feature segmentation, the most critical step in quantitative microscopy, must be objective and reproducible. However, pores in concrete are difficult to segment due to their small size and irregular nature.

Thus, we have developed a technique using the inflection point of the cumulative brightness histogram of a BSE image3. This represents a critical transition where the segmented pore areas begin to ‘overflow’ to the surrounding paste (Fig. 3).

The ‘overflow’ method is more consistent and reliable than existing methods, and overcomes the difficulty in defining the true pore boundary. Once the features of interest are segmented, various measurements can be made such as size, volume fraction, surface area, shape, orientation and spatial distribution (Fig. 4-6). This is carried out using stereology, which relates measurements made on two-dimensional images to the actual three-dimensional structure.

When a sufficiently large number of images are analysed, typically 30-50, the obtained results are representative. BSE imaging is ideal for characterising the pore structure because of its high resolution and ability to cover a wide range of pore sizes. It images the pores and identifies the solid phases to establish where the pores are in relation to other phases. The methods developed in this study have enabled and facilitated much of our subsequent work, such as modelling mass transport properties, analysing the composition of hardened concrete and investigating deterioration.

References:

- H.S. Wong, N.R. Buenfeld (2006), Patch microstructure in cement-based materials: Fact or artefact? Cem. Concr. Res., 36, 990-997.

- H.S. Wong, N.R. Buenfeld (2006), Monte Carlo simulation of electron-solid interactions in cement-based materials, Cem. Concr. Res., 36, 1076-1082.

- H.S. Wong, M.K. Head, N.R. Buenfeld (2006), Pore segmentation of cement-based materials from backscattered electron images, Cem. Concr. Res., 36, 1083-1090.

- H.S. Wong, N.R. Buenfeld (2006), Euclidean distance mapping for computing microstructural gradients at interfaces in composite materials, Cem. Concr. Res., 36 1091-1097.

Contact us

Prof Nick Buenfeld

Tel: +44 (0)20 7594 5955

E-Mail: n.buenfeld@imperial.ac.uk